Centrifugal Fan and Blower Manufacturer

Less noise, higher performance

Leading Design Concept, Excellent Product Quality

As a leading centrifugal fan manufacturer in the industry, Langdi has invested a lot of money in product R&D and manufacturing, built a modern and well-equipped scientific research building, equipped with a fan team with decades of R&D experience, and long-term cooperation with universities and scientific research institutions , to achieve a modern R&D platform.

Langdi's products are widely used in household air conditioners, commercial air conditioners, central air conditioners, HVAC purification, ventilation equipment, ducted air conditioning units, etc.

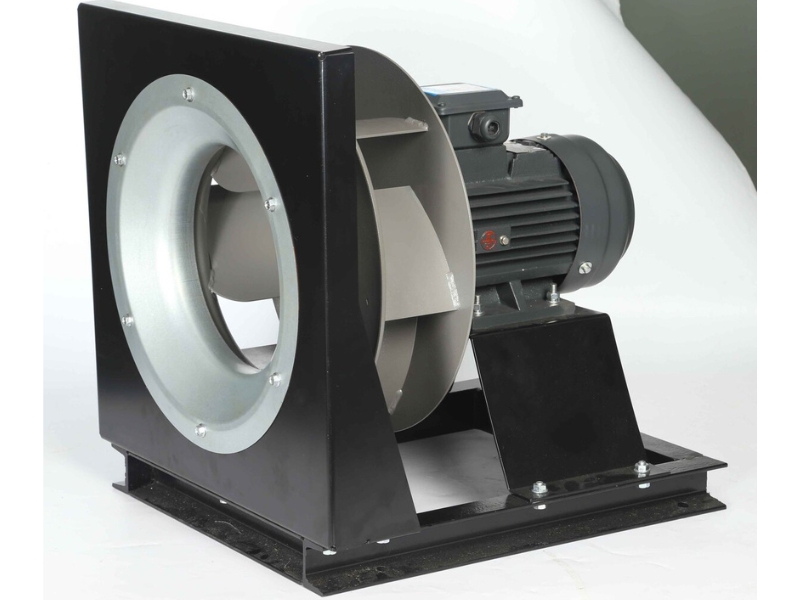

Types of Centrifugal Fans and Blowers

Single Inlet Backward-Curved

Double Inlet Backward-Curved Belt Driven

Double Inlet Forward-Curved Belt Driven

Double Inlet Forward-Curved Direct Driven

Single Inlet Forward-Curved

Why Choose Us

Our Qualifications

Langdi Buying Guide to FAQs

Our Capabilities

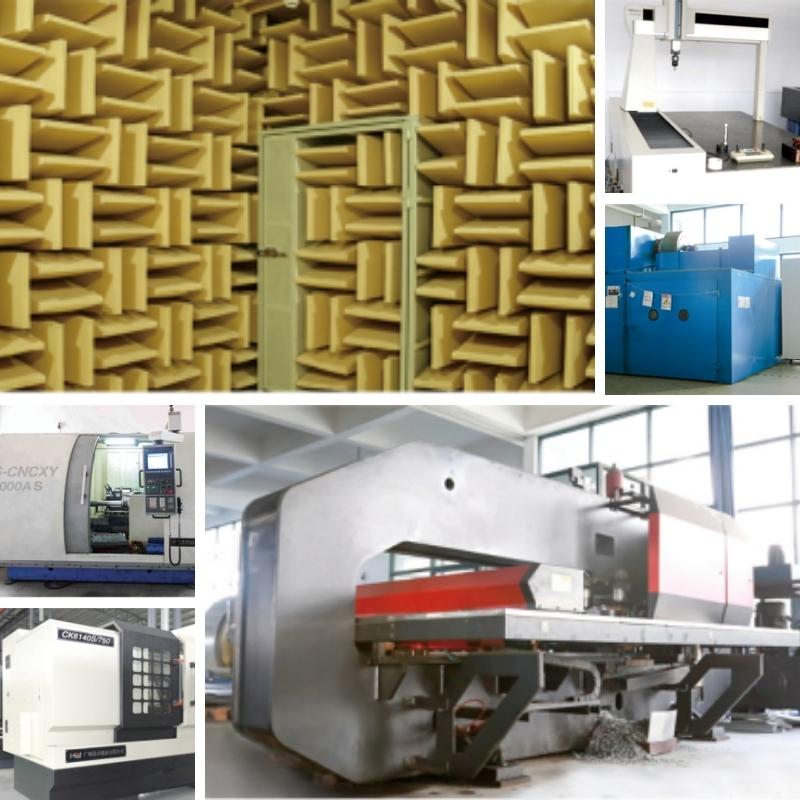

R&D Facility

-

Langdi Group has a modern science and technology building, a professional noise test room, an air volume test system with a volume of over 100,000, and high-end R&D equipment such as three-coordinate precision measurement.

-

Using advanced CFD simulation software, it is equipped with a professional R&D team with decades of wind turbine experience.

-

Langdi has long-term cooperation with many colleges and universities and scientific research institutions, and continues to invest R&D funds every year to create a modern R&D platform.

-

The company has more than 50 fan design patents, and its products are widely used in commercial air conditioners, household air conditioners, central air conditioners, HVAC purification and ducted air conditioners.

Production Facilities

-

12 production bases have been constructed across the country outside the headquarters of Lundy.

-

Our production workshop is equipped with a professional assembly line and QC team to complete the production capacity requirements of each customer under the premise of ensuring quality.

-

Our motor workshop is equipped with a technical team with more than ten years of technical experience, as well as various types of modern production and testing equipment, integrating production, testing and research and development.

-

Langdi has independent research and development and mold manufacturing experience, and all molds are independently designed and manufactured.

Enterprise Qualification

-

The product has obtained the triple national energy efficiency certification of AMCA aerodynamics, noise and energy efficiency.

-

The first in the industry to pass ISO 9001 quality management system certification and ISO 14001 environmental system certification

-

Selected for many times as Zhejiang famous brand, Zhejiang famous brand product

-

For many years, it has been awarded the title of gold supplier by well-known domestic and foreign brands such as Midea, Gree, LG, Mitsubishi, etc.

Choose the Best Centrifugal Fan Manufacturer

Over the years, Langdi has been cooperating with international industry giants for many years, providing reliable quality, competitive price and strong production capacity.

As a leading manufacturer and supplier of Centrifugal Fan in China. We pride ourselves on providing our customers with high-quality products and continually meet the ever-increasing demands of the industry. We believe that we can meet all your needs.

Centrifugal Fan: Guide to FAQs

This article will give you a detailed introduction to the fans used in the ventilation system, and make some tips for purchasing.

Centrifugal Fans: Buying Guide

1.What is a centrifugal fan?

A centrifugal fan is a mechanical device used to move air or other gas at an angle to the incoming fluid.

Centrifugal fans are also often called blowers or squirrel cage fans (because they look like hamster wheels)

Centrifugal fans use the kinetic energy of the impeller to move the airflow, which in turn moves against resistance created by ducts, dampers, and other components. Centrifugal fans displace air radially, changing the direction of airflow.

2.What are the characteristics of using a centrifugal fan?

The centrifugal fan is a constant volume device, which means that at a constant fan speed, the centrifugal fan will drive a constant volume of gas.

Centrifugal fans use the kinetic energy of the impeller to displace air radially, changing the direction of the airflow (usually 90°). They are robust, quiet, reliable, and capable of operating in a variety of conditions.

3.Why are centrifugal fans worth investing in?

-

Best-in-class energy efficiency.

Constant airflow enables centrifugal fans to generate energy up to 84% static efficiency. These higher efficiency levels are ideal for maintaining larger air systems.

-

Enhanced durability.

These fans are durable enough to perform well in the most corrosive and aggressive environments.

-

Limit the ability to overload.

Some centrifugal fans are equipped with a non-overload horsepower curve, which ensures that the motor does not overload when it exceeds capacity.

-

Easy to maintain.

Lighter material fans can be easily cleaned when you think it is necessary.

-

High versatility.

Centrifugal fans are available in a variety of airflow/pressure combinations, and they can handle a variety of airflow conditions.

-

Various sizes.

These fans are available in a variety of sizes to suit different applications - such as in tight spaces or hard-to-reach areas.

-

Customizable

The popularity of the centrifugal fan is largely due to its customizability, which comes in many sizes to help you in different spaces.

4.What types of centrifuges are there?

There are four basic types of centrifugal fans, each of which has a suitable application area.

-

Radial

High pressure fan with medium airflow.

-

Forward Curve

Medium pressure, high airflow fan.

-

Backward Curve

High-pressure, high-flow, high-efficiency fans.

-

Airfoil

Highest efficiency fan, best for clean air applications.

5.What conditions need to be considered when using a centrifugal fan?

Installation Environment

-

The environment needs careful consideration, because it affects performance, durability, etc., which seriously affects efficiency and work interests.

-

Outdoors consider installing a Totally Enclosed Fan Cooled (TEFC) motor on a direct drive unit, or on a belt drive unit with a weather cover included.

-

Dirty or dusty environments TEFC motors are best suited for extended life and optimized efficiency.

-

Corrosive environment In wet and humid environment, it is recommended to use stainless steel blower, preferably stainless steel cleaning motor.

-

Hazardous environments Consider non-sparking blowers with explosion-proof motors, such as radial or high pressure blowers.

Air quality

-

Clean Air Consider forward-bend, rear-bend, or airfoil blowers for greater efficiency.

-

For slightly dusty air consider radial or high pressure blowers. For very light, non-abrasive dusts, a backward-sloping blower can be used.

-

Heavier, more abrasive dust, filings and shavings For this environment, you may need an industrial material handling blower.

-

Corrosive In wet, humid, corrosive environments, you should choose stainless steel blowers, preferably stainless steel cleaning motors.

-

Combustible If there is combustible dust or particles in the air, choose a non-sparking blower such as a radial or high pressure blower with an explosion-proof motor.

-

The air temperature uses belt drives with drums at higher temperatures. If the temperature climbs above 250°F, consider using an industrial blower with a heat sink.

6.What are the applications of centrifugal fans?

Centrifugal fans have a wide range of usage scenarios, bringing a lot of help to production and life.

Centrifugal fans are used for:

-

Heating, Ventilation and Cooling (HVAC) or Building Ventilation Systems

-

Dust collection and extraction fans

-

Air Conditioning System

-

Air Filtration and Pollution Control Devices

-

Industrial conveyor

-

Large-capacity dryers (for example, those used in commercial car washes)

-

Fluidized bed aerators (devices used to add oxygen to water or other fluids, i.e. sewage aeration)

-

Backwash (self-cleaning) filter

-

Gas boosters (for moving high pressure gas or increasing gas pressure)

-

Vehicle engine

-

Industrial furnace

7.What is the working principle of a centrifugal fan?

The working principle of the centrifugal blower is relatively simple. They employ centrifugal force - the force that is created when an object moves around a point of rotation.

In effect, the kinetic energy of the impeller rotation is transferred into the air or gas.

This means that the impeller has the mechanical function of a rotor—the rotating part that introduces energy into the system.

The opposite of a rotor is a turbine, a device that removes energy from a mechanical system for use elsewhere.

8.What are the components of a centrifugal fan?

The main components of the centrifugal fan are:

-

Centrifugal Fan Housing

-

Centrifugal fan impeller

-

Air duct inlet and outlet

-

transmission shaft

-

Drive unit

-

Fan Dampers and Blades

-

Inlet and Outlet Piping

-

Centrifugal fan fan blades

-

Fan discharge box

To complement the application, other required components such as bearings, couplings, etc. may be used.

9.Is the centrifugal fan loud?

Centrifugal fans primarily pressurize the air within the blower housing. Compared to axial fans, they produce a steady, high-pressure airflow, but they move less air. They can be equipped with forward or backward curved impellers for blowing or suction. Like axial fans, they also come in AC and DC powered models, depending on the application, but centrifugal fans generally require more power to operate than axial fans. Both centrifugal blowers and axial fans produce audible and electromagnetic noise, but centrifugal fans are a bit louder than axial fans.

10.What are the standards for centrifugal fans?

The selection of centrifugal fans must pay attention to whether they meet relevant standards and certifications.

You should ask the centrifugal fan manufacturer to provide relevant certificates when you choose related products:

-

AMCA

-

CRAA

11.What is the difference between a centrifugal fan and an axial fan?

Centrifugal fans and axial fans, which are typically used in residential, industrial, and commercial applications, are drawn for comparison.

There are many differences between the two, and in quite a few occasions, they have a lot of differences.

An axial fan is a fan that forces the extracted air to move parallel to the axis on which the blades rotate. Centrifugal fans draw air at right angles to the fan inlet and rotate the air outward to the outlet through deflection and centrifugal force.

Compared with centrifugal fans, axial fans with the same flow and pressure have the following differences:

-

Centrifugal fans are noisier

-

The air pressure of the centrifugal fan is higher

-

Centrifugal fans have high efficiency

-

Axial fans have higher power consumption

-

Axial fans operate at lower static pressure for higher efficiency

Therefore, axial fans are typically used for high volume air movement, such as warehouse exhaust or room circulation, while centrifugal fans are used to move air in ducted applications, such as houses or typical office environments.

12.What type of centrifugal fan should be used in HVAC?

Centrifugal fans are better suited for larger systems: air handling units, air pollution and filtration systems, and drying systems. Incredibly energy efficient and versatile, these fans are available in a variety of models so you can find one that fits in tight, hard-to-reach spaces. They are also an excellent choice for dedusting, glass tempering and incineration systems.

Choosing the right fan for your HVAC system is critical to its efficiency and performance. For example, an axial fan won't do a good job of managing drag compared to a centrifugal fan of the same size in an air filtration system. Using an axial fan for this purpose will result in poor system performance and may result in additional maintenance and repairs. Although it will be cheaper initially, it will cost more in the long run and will not perform the way you would expect from a system of this type. Also, using centrifugal fans in unneeded cooling towers can cause unnecessary noise and increase costs.

13.How to choose the right centrifugal fan for the job?

After you have determined that you need to use a centrifugal fan for your business, it is necessary to consider these matters, which will seriously affect your business development and subsequent maintenance costs.

Pipeline

Early in the design process, pipeline performance and efficiency should be considered. This will affect the final design in terms of overall cost, compactness of the fan and operating cost.

Total airflow

Airflow is measured in cubic feet of air per minute (CFM). When conveying material, ensure that the pipe or hose size has adequate CFM.

Static pressure

Airflow resistance or static pressure is caused by the passage of air through pipes, hoses, pipes, filters and other factors. Static pressure is in inches of water gauge (SPWG).

Density

Density changes due to changes in temperature and/or air pressure should be corrected for standard conditions.

Air temperature

The temperature of the air passing through the fan or blower can affect the performance of the fan or blower.

Altitude

The altitude at which the fan or blower operates can also affect the performance of the fan or blower.

Material handling

If the material will be conveyed by a fan or blower, the material characteristics should be considered.

Ambient temperature

The air temperature or ambient temperature outside the fan or blower can affect the operation of the fan or blower.

Safety conditions

Special accommodation may be required if any material passing through the blower is flammable or combustible.

14.How to properly care and maintain your centrifugal fan?

You always need to be sure if the centrifugal fan is functioning properly, here are some quick tips:

Turn the fan impeller by hand at least once every two weeks to apply grease to the bearing components.

Maintain proper bearing lubrication to avoid any failures.

Periodically inspect the fan impeller for wear, corrosion, or material buildup. Clean or replace as necessary.

Tips

In addition we have detailed maintenance guidelines in the instruction manual of the centrifugal fan, here we provide some quick tips:

-

Carefully inspect the rotor for wear, damage and cracks. Any damaged or severely worn rotors will need to be replaced. Equipment with damaged rotors should not be used. Observe all lockout requirements when performing rotor inspections.

-

Use only the base, mounting brackets, or lifting lugs provided on the fan assembly to lift the centrifugal fan.

-

Never lift the fan by its wheels, shaft, motor, motor bracket, housing inlet, housing outlet, or any other part of the fan that is not intended for lift.

-

Trainers must make all lifting decisions.

-

Centrifugal fans that have been stored for a period of time must be protected from dust and moisture.

-

The device will remain clean and dry if covered with a tarp. Dark plastic tarps should not be used as it will add moisture.

-

Bearings should be cleaned with fresh grease once a week to prevent moisture exposure for long-term or outdoor storage.

-

Idle motors should be stored in accordance with the manufacturer's instructions.

-

Any nearby vibration must be shielded from the fan. High vibration in the fan storage area can damage the fan and motor bearings.

15.Why purchase centrifugal fan manufacturers from China?

Centrifugal fan manufacturers in China have the following advantages, which make your business fully guaranteed:

-

High-quality workforce

-

Young and ample high-skilled population

-

Always keep costs down.

-

Infrastructure and Geography

-

Stable Supply Ability

16.How to find centrifugal fan manufacturers from China?

Ways to find a centrifugal fan manufacturer in China include

Online platform

Online platforms such as Alibaba and Made in China are ideal places for different centrifugal fan manufacturers to market to customers.

Manufacturers can usually offer you different prices and after-sales services.

When searching on these sites, you must make sure that you are selecting a manufacturer and not a distributor or trader.

Also, do not trade with a specific manufacturer until you have verified their credentials.

The benefit of having a large number of manufacturers on these sites is that you can negotiate or select the right manufacturer for your automatic power press.

You also have the opportunity to negotiate the price of the product.

Google, Bing search

Most good centrifugal fan manufacturers have their own websites to advertise their products.

However, many excellent Chinese manufacturers do not pay attention to this or start late, but this does not mean that they cannot provide excellent products.

So it might be hard to find them on the first few pages, but you can check out a few pages with many good centrifugal fan manufacturers to choose from.

Or you can add "China" to your keyword to see more Chinese manufacturers.

Purchasing agent

Many purchasing agents in China are aware of different centrifugal fan manufacturers in China.

They understand the production capacity and pricing of these manufacturers.

These are the important specifications your purchasing agent can help you when searching for centrifugal fans

Sourcing agents can also save you the trouble of finding reliable manufacturers, as they usually have a ready list for you to choose from.

The main limitation of using a purchasing agent is the high cost of finding a manufacturer.

There's no way to compare what you pay here with what you might lose if you bet on finding a manufacturer.

Trade shows and trade shows.

Whenever a Chinese trade show is held in your country or China, you should expect Chinese manufacturers to showcase their products.

This allows you to interact with different manufacturers and ask them about different aspects of their manufacturing process.

The advantage of this method is that you can meet face-to-face with a specific manufacturer.

This allows you to negotiate different specifications with the manufacturer.

Common trade shows and fairs in China include: Canton Fair, etc.

Crucially, once you have an agreement with a specific manufacturer, you need to visit their premises before starting production.

Choose the Best Centrifugal Fan Manufacturer

Langdi is a leading centrifugal fan manufacturer and supplier in China. Our company provides customers with various specifications and models of centrifugal fans. You can check the specifications directly from our website. In addition, if you have your own needs, you can develop with our R&D team to meet your needs.

If you are looking for a suitable centrifugal fan, please contact us today.